配件

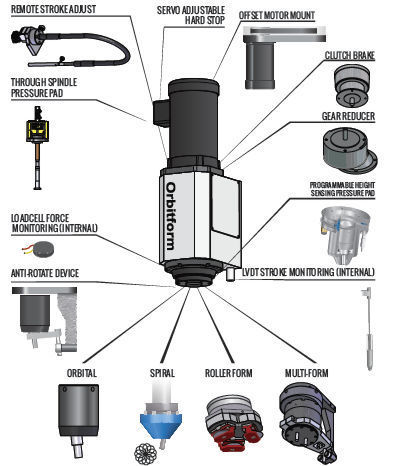

Orbitform offers many accessories to improve the orbital, radial, or impact processes, increasing throughput, reducing cycle time, increasing safety, reducing the machine footprint, and improving the operator interface. Options such as process monitoring and/or process control can greatly reduce scrap and assure consistent quality.

- 型号

- Multi-Point

- Multi-Spindle

Multi-point orbital heads help you get in, get out, and get the assembly job done. Load parts once. Cycle the machine once. Perform the entire assembly operation in just one cycle even where there are up to ten posts being formed or rivets being riveted. The multi-point forming heads from Orbitform help you achieve this. Orbitform's multi-point orbital forming heads are available in a wide range of sizes, capacities, number of forms per head, form heights and form spacing. The multi-point forming process is beneficial for cost reduction, quality enhancement, and cycle time minimization for high volume product assembly applications.

Advantages of the Multi-Point Forming Process

The Multi-Point orbital riveting process is advantageous as it forms multiple points in an assembly at the same time. The Multi-Point process helps reduce cycle time and lower the amount of load / unload involved in an assembly operation. The quality and repeatability of an assembled product is also improved due to fewer part handling instances. You can rest assured you are incorporating the most efficient and cost effective assembly method when Multi-Point forming is applied.

Multi-Point forming heads are eccentric-driven with integral, fixed-center forming peens normally configured with close center distance applications. The forming must happen on the same plane since each point of the Multi-Point head is on the same vertical position. The orbital motion is generated by the eccentric action of the Multi-Point forming head and it is important to keep in mind that an anti-rotate device is required with each Multi-Point forming head to keep the forming head in place during the entire forming or assembly process.

Standard Features of Multi-Point Orbital Forming

- Eccentric-driven with fixed-center forming peens used for close center distance applications

- Center distance range of 0.188 in (4.7 mm) to 3.0 in (76.2 mm)

- Forming capacity range of 0.125 in (3.18 mm) to 0.75 in (19.1 mm) finished head diameter (mild steel)

- Number of forming points range from 2 - 10

- All forms must be the same height

- Anti-rotate device is required with each Multi-Point forming head to keep the forming head in place

Orbitform supports your assembly application with our factory trained sales engineers and applications specialists along with a strong team of lab technicians, machine builders, and assembly experts. Please use our expertise to help you deliver the solution for any Multi-Point forming process or Multi-Point riveted assembly.

Advantages of the Multi-Spindle Riveting and Forming Process

The multi-spindle orbital riveting process is advantageous as it forms multiple points in an assembly at the same time. The multi-spindle process helps reduce cycle time and lower the amount of load / unload involved in an assembly operation. The quality and repeatability of an assembled product is also improved due to fewer part handling instances. You can rest assured you are incorporating the most efficient and cost effective assembly method when multi-spindle forming is applied.

Multi-spindle forming heads are housings equipped with internal gears, shafts, and bearings connecting two or more orbital heads to the main spindle of the Orbitform powerhead. The multiple orbital heads being driven by the multi-spindle head result in several orbital forming heads with a single peen each forming a single post simultaneously.

Multi-spindle orbital forming is not restricted to a single plane since separate spindles and orbital heads are used for each rivet. Thus, the multi-spindle heads can be designed for different forming heights in relationship to one another. The ability to form posts of differing heights or to assemble rivets on different planes is a major advantage of the multi-spindle assembly method.

The center distance between rivets or between form positions for multi-spindle applications are dependent on rivet size and rivet material along with the corresponding orbital head size required to form the rivets.

Multi-spindle head standard features:

- Uses orbital heads with peens on the end of separate spindles to form the work piece

- Center distance range of 1.70 in (43.2 mm) to - 12.0 in (304.8 mm)

- Forming capacity range of 0.125 in (3.18 mm) to 1.0 in (25.4 mm) finished head diameter (mild steel)

- Number of forming points ranging from 2 - 10

- Variable forming heights possible

Orbitform is here to support your specific assembly applications with our sales engineering team and our applications specialists along with a strong team of lab technicians, skilled machine builders, and assembly system experts. Please use our expertise to help you deliver the solution for any multi-spindle forming process or multi-spindle riveted assembly.