Orbitform’s Assembly Products & Services

Orbitform designs and builds assembly equipment for manufacturing. Since 1984, Orbitform has delivered over 7,000 assembly machines and custom assembly systems to a wide range of customers and industries around the world.

We Build Machines For:

- Orbital Riveting & Fastening

- Impact Riveting

- Roller Forming

- Hot Upset Forming & Riveting

- Projection & Resistance Welding

- Assembly Automation

- Conveying Systems

- NEW Flush Self-Piercing Riveting

We Provide Services For:

- Assembly Analysis

- Tooling Development

- Batch Production Runs

Orbitform 视频

Orbitform Overview Video

Learn Even More

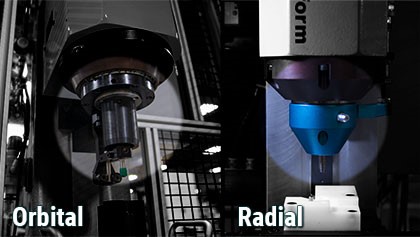

For more information about Orbitform, the services we offer, and permanent part assembly, read our white paper, catalog, or journal.Orbital riveting and forming is a cold forming process using a peen tool held at a fixed angle to create a sweeping line of pressure around the part, progressively forming the material with each rotation. This process reduces the amount of forming force required by approximately 80% of a standard press.

详细介绍

The radial forming and riveting process is similar to the orbital riveting and forming process, but with radial riveting and forming the material is displaced from the center outward in a rosette or rose curve pattern. The radial riveting process is often the optimal assembly solution when working with small rivet shank diameters, delicate rivet materials, or unsupported rivet assembly applications. Orbitform will help you define the appropriate riveting process, whether radial or orbital.

详细介绍Impact Riveting is an assembly process using force to fasten two things together permanently using a wide variety of rivet and material options. Cycle time is fast and operation is simple, giving you an assembly advantage.

详细介绍Roller Forming is a non-impact process using a spinning Roller Head with two or more rollers to apply a symmetrical force to form the part. Roller Forming is used for flaring, forming a lip, crimping, or forming a groove in cylindrical parts too large for other processes. Assembly applications range from bearings, ball joints, electrical sensors, fuses, and many others.

详细介绍The Hot Upset forming and riveting process uses heat and pressure to form the fastener. The material being formed becomes malleable and collapses under pressure applied by the Powerhead. Using this process, it is possible to form a round fastener into a square hole, creating very high torque joints. This makes the process excellent for forming parts that will incur high vibrational fatigue.

详细介绍

Orbitform offers optional process monitoring and process control solutions on all of our assembly systems. Our customers select the process monitoring or process control package best fitting their assembly application requirements. Force, pressure, stack-up height, dwell time, finished form height, rivet presence, and other process parameters can be monitored and/or controlled with Orbitform process monitoring and process control solutions.

详细介绍Orbitform's Palletized conveyor use pallets to carry individual parts between assembly stations, machining centers, part washers, etc. Pallets move on the conveyor asynchronously, and can buffer prior to entering and after exiting a work station. Traffic controls release pallets as the work station or operator is ready to receive them. Orbitform engineers understand the demands of the factory floor and developed a robust design for 24/7 uptime and years of trouble free operation. Orbitform’s palletized conveyors are a cost effect solution to automate production, increasing up-time, quality, and throughput to improve your bottom line. For a quote contact Orbitform's automation specialist Brent Parker at 517-787-9447

详细介绍Orbitform’s Part on chain Conveyor Systems are designed for high volume production, minimal contact force, and part buffering. With exceptional wear characteristics, parts ride directly on a dense array of plastic rollers or on a flat low-friction surface allowing parts to flow freely with minimal friction reducing collision force between parts, reducing static build-up (as seen with belt conveyors), and eliminating pile-up issues during part accumulation. Traffic control includes part metering, part singulation, programmable stops, and push-off line transfers. For a quote contact Orbitform's automation specialist Brent Parker at 517-787-9447

详细介绍

All Orbitform tooling is designed, developed, manufactured, and tested in-house...at Orbitform. Thereby eliminating the finger pointing found with some assembly equipment suppliers. In addition, our engineers can make recommendations based on your assembly application to deliver ideal tooling for your assembly machine(s). We look forward to helping improve your assembly process.

详细介绍

We utilize every single one of our areas of expertise to offer our customers the answer to their assembly equipment goals. When you need to optimize your fastening or assembly process, Orbitform is the industry leader. We offer a wide range of automated assembly system options to help you increase throughput, reduce cost, improve quality, and satisfy your customer. Our unbiased approach assures you will receive the correct assembly system to fit your requirements.

详细介绍

Orbitform has you covered for your small production run needs. Whether you need to assemble 5 parts, 50, 500, or even 5000 parts, Orbitform can help you get the assemblies produced. Hot jobs, last minute samples, prototyping, product development, let us know how we can jump through hoops to help you! Even if you need to do some machining and/or fabrication work along with the assembly process, Orbitform can help you make it happen.

详细介绍Orbitform offers both fixed tool resistance and projecting welding systems custom engineered to suit your application in both AC and DC currents. Resistance welders pass electrical current through a localized area between two or more layers of thin metal, heating the area until melting occurs to form a bond. In projection welding a current is passed through a raised section or projection and a part to be bonded.

详细介绍